The concept of 6S is derived from the Japanese 5S method used in industries and in this write-up. Preeyan touches upon how things can be if we follow this in our day to day routine. Read more in the weekly column, exclusively for Different Truths.

6S was a new concept to me and initially, I went looking for what it was. Then when I actually got into the details of it I realised how simple but effective concept this is at your workplace. It is not only something you follow it becomes a way of life. 6S is today’s standard of any workplace, does not matter if it is a retail store or a giant manufacturing set up. Following this makes life simpler and makes your workplace look good.

The concept of 6S is derived from the Japanese 5S method used in industries and in this write-up I would like to touch upon how things can be if we follow this in our day to day routine.

The Japanese are very systematic people and that’s how they have made it to superpower status being such a small country. Today, their cars can beat European technology hands down and they are driven everywhere in the world. Toyota, Suzuki, Mitsubishi, Nissan are just a few names I recall. Take any field and you will see Japanese technology is rated very highly. One of the key reasons is because they are very systematic and disciplined people. The concept of 5S is just a simple tool we can use to start this transformation.

everywhere in the world. Toyota, Suzuki, Mitsubishi, Nissan are just a few names I recall. Take any field and you will see Japanese technology is rated very highly. One of the key reasons is because they are very systematic and disciplined people. The concept of 5S is just a simple tool we can use to start this transformation.

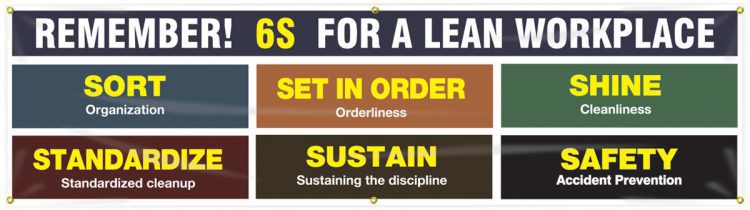

The concept of 6S is noting but 5S + Safety. What do these 5S’ stand for? They are Seiri (Sort), Seiton (Set in order), Seiso (Shine), Seiketsu(Standardise), Shitsuke (Sustain) and Safety.

Simple six words which coincidently starts with ‘S’ in English as well. Hence 6S. It sounds very simple and how we go about it is what makes the difference. If you come to think of it, we actually follow this at home or rather our mother practices this at home. It is in the “kitchen”. Mom always knows where you find sugar, salt, masala, dal, flour, milk, tea – name it and it has a place in the kitchen. And it will remain so forever.

So, what is done in the kitchen by our mom, which we failed to observe, will help us set the perfect workplace.

Seiri or Sort: It means that we first sort out what we need in order, then we identify a place for it to go. Now, this in a workplace is simple, you segregate all papers lying on the desk, the pens and other accessories we hold in our workplace. Many times, we are actually losing time looking for things here and there, because we have never sorted our workstations. Once you do this it makes things simpler. Even documents in your computer, e-mails, etc. can also be sorted. We just have to learn how to sort this. Like, for example, I have an e-mail box that has multiple folders by the category of importance such as directors, teams, etc. and I have set rules which moves the emails directly to the folders. Which means that I never get to lose a single email. Or if I am looking for something I do not waste too much time in the search process.

Seiton or Set in Order: Now that you have sorted all items, you need to set them in order which means that you define a specific location or position for everything you have sorted. This means that you have a designated place for everything. Has to be everything, no exceptions!

Seiso or Shine: It is nothing but polish, which means that you keep clean, and make it look good. There have to be no excuses. I remember a meeting I had with a client some 8 years back, I had been using a laptop for almost 4 years and suddenly my client asks me, “Is this your new laptop?” and I had to tell her it is 4 years old and she says, “man do you keep cleaning your laptop every day” for which I said “yes I do” and that machine I used for two more years and then another colleague of mine, used it for 3 more years before we discarded it. This is something I learned from my boss as he too was like that in terms of maintaining his assets. Simple but you need to set your mind to do this. Shine!

Saiketsu or Standardise: Everything that needs to be successful needs a level of standardisation, many companies come up with policies like ‘clean desk policy’ etc. such that their employees are forced to follow it, they even reward or penalise you for the level of maintenance. Though I am not against it, I feel, it is to educate people on the advantages of it than forcing them to do something. Standardisation is something everyone has to do, the way your mom will set the kitchen, the same way she does in every house you may have moved to.

Shitsuke or Sustain: Everything you implement will only be considered successful only if it can sustain and easily be followed. Your effort has to continue to ensure that, what you have done till now, needs to last forever. And for this, you should not accept anything out of place. You have to become strict in maintaining standards you have set for yourself.

Safety: At a workplace, safety standards have to be kept high. There should be no compromise to safety measures in the workplace, like loose wires, unnecessary electrical extensions and anything that looks broken or can be a hazard to safety has to be considered.

Following 6S makes your workplace better organised, which means that you get to save time on many occasions without you realising it. It makes you more efficient and in the end, you save a lot of time, effort and money without realisation of the fact. Try it, and then see how it works out for you. It starts with you to implement this concept.

Hope you had a good read, have a wonderful week ahead.

Cheers!

©Preeyan Abraham

Photos from the Internet

#6S #The6SInWorkplace #Workplace #TipsForWorkplace #HealthyWorkRelationship #Career #SuccessInCareer #JobsAtTheRateCareer #DifferentTruths

By

By

By

By