The fourth industrial revolution, with the use of data and machine learning, is taking forward the legacy of the third revolution, opines Joydev. An exclusive for Different Truths.

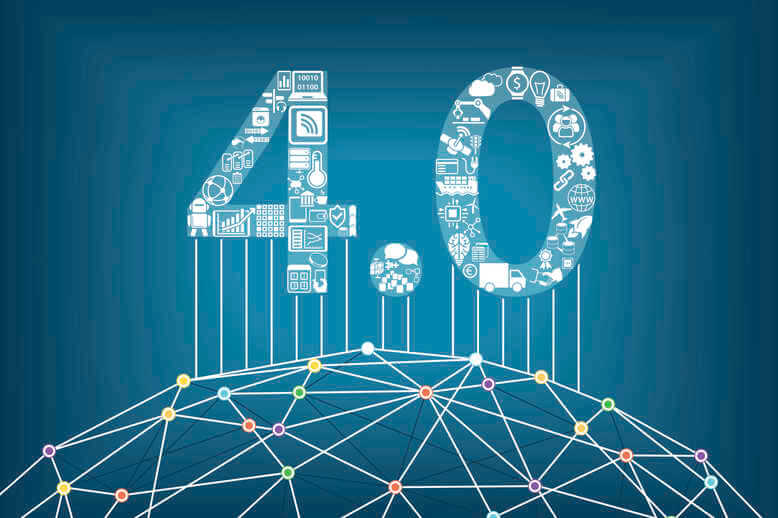

When I say Industry 4.0, that doesn’t simply mean the 4th generation of industry. It is a complete transformation of the modern-day industry. The first industrial revolution that was recorded between 1720 to 1840, brought about a colossal change in the manufacturing sector. From mechanisation through water and steam power, the first industrial revolution slowly shifted to the second, with mass production and assembly lines using electricity. Similarly, the fourth industrial revolution will take forth what was started in the third revolution – the adoption of computers and automation. The fourth industrial revolution, with the use of data and machine learning, is taking forward the legacy of the third revolution, ‘smartly’ and with autonomous systems.

When I say Industry 4.0, that doesn’t simply mean the 4th generation of industry. It is a complete transformation of the modern-day industry. The first industrial revolution that was recorded between 1720 to 1840, brought about a colossal change in the manufacturing sector. From mechanisation through water and steam power, the first industrial revolution slowly shifted to the second, with mass production and assembly lines using electricity. Similarly, the fourth industrial revolution will take forth what was started in the third revolution – the adoption of computers and automation. The fourth industrial revolution, with the use of data and machine learning, is taking forward the legacy of the third revolution, ‘smartly’ and with autonomous systems.

I-scoop defines Industry 4.0 as the ‘digital transformation of manufacturing/production and related industries and value creation processes.’

I-scoop defines Industry 4.0 as the ‘digital transformation of manufacturing/production and related industries and value creation processes.’

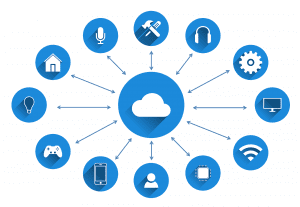

The introduction of computers during the period of Industry 3.0 was an invigorating stimulus to the complete ecosystem. This addition of an exclusively new technology disrupted the entire processing industry. Industry 4.0 takes this disruption one step ahead with connectivity, allowing instant communication between gadgets (Yes, gadgets). Technologies like cyber-physical systems, the Internet of Things (IoT), and the Internet of Systems combined together to make the dreams of a connected industry, i.e., Industry 4.0 or smart factory, a reality. Just like our phones became smart, factories didn’t want to lag, and they became smart too.

The modern control systems have software embedded to them, which disposes an Internet address to connect and get addressed via the Internet of Things (smart-machines). This enables the products and the means of production to get a network to ‘communicate’ with each other, thus opening up new ways of production, value creation, and real-time optimisation.

The modern control systems have software embedded to them, which disposes an Internet address to connect and get addressed via the Internet of Things (smart-machines). This enables the products and the means of production to get a network to ‘communicate’ with each other, thus opening up new ways of production, value creation, and real-time optimisation. As a result of the support of smart machines that keep getting smarter each day, our factories have become efficient, more productive, and less wasteful. Here is where the true potential of Industry 4.0 gets unleashed.

The role of IoT is indeed significant in the Industry 4.0 era. Still, there are several other technologies, apart from the IoT, who have their role to play in making Industry 4.0 a buzzword this decade. Cloud computing, big data (advanced data analytics), artificial intelligence (AI), storage and compute power at edge networks (edge computing), data analysis, data communication, enterprise resource planning (ERP), which has now become i-ERP, programmable logic controllers, and many more have their individual and definite roles to play in the formation of Industry 4.0.

While there are still many organisations wondering about the implementation of Industry 4.0 into their unique use cases, some are already riding on the benefits of it. Besides implementing the technology into the use cases, those beneficial companies are also preparing for the future where smart machines are likely to dominate the businesses.

While there are still many organisations wondering about the implementation of

Industry 4.0 into their unique use cases, some are already riding on the benefits of it. Besides implementing the technology into the use cases, those beneficial companies are also preparing for the future where smart machines are likely to dominate the businesses. Having said this, let us look at some key application areas of Industry 4.0.

Cloud and the IoT: IoT is undoubtedly a key component of Industry 4.0, which is characterized by connected devices. Besides assisting in the internal operations, IoT, with the use of the cloud environment, optimizes the equipment and operations by leveraging the insights of others. It enables the smaller enterprises, who wouldn’t be able to leverage the insights of their own, take benefits from the public cloud platforms, where a huge data is stored.

Autonomous robots can perform any sort of tasks they are trained on, for example, packaging of products and getting them ready to ship, with minimal waste of time and high accuracy.

Robots: Industry 4.0 has made the dream technology ‘robotics’, which once was only possible for large enterprises with large budgets, affordable and available to every organisation, irrespective of their sizes and budgets. Autonomous robots can perform any sort of tasks they are trained on, for example, packaging of products and getting them ready to ship, with minimal waste of time and high accuracy.

Autonomous Vehicles (AV): Some of the developed streets of the U.S. have  already started witnessing the autonomous vehicles, i.e., the vehicle without a human driver. AVs in the form of cranes and trucks are being used in the shipping yards that have brought down the accident levels drastically. Very less number of errors have been recorded since the AVs have taken over the normal vehicles.

already started witnessing the autonomous vehicles, i.e., the vehicle without a human driver. AVs in the form of cranes and trucks are being used in the shipping yards that have brought down the accident levels drastically. Very less number of errors have been recorded since the AVs have taken over the normal vehicles.

Industry 4.0 opens up ample opportunities for businesses to optimise their operations quickly and efficiently.

Future Opportunities: The connected machines are designed to gather a huge volume of data that can be analysed to identify patterns and insights that would be impossible for a human to do in a given timeframe. Industry 4.0 opens up ample opportunities for businesses to optimise their operations quickly and efficiently.

The disruption caused by Industry 4.0 is not going to end any soon. Come again a year later, and we will have a stack of new use cases to discuss.

Photos from the Internet

By

By

By

By